Mold Your Success: The Ultimate Guide to Injection Molder Services for Your Business

Welcome to the ultimate guide on injection molder services for your business! As a crucial aspect of the manufacturing industry, injection molding plays a significant role in transforming raw materials into a diverse array of products. The process of injection molding involves melting plastic pellets and injecting them into a mold to produce intricate shapes and designs with precision and efficiency. By harnessing the potential of injection molder services, businesses can meet their production needs effectively while ensuring high-quality end products.

Types of Injection Molding Processes

Injection molding processes can be categorized into several types based on different factors such as the material being used, the complexity of the design, and the production volume required. Understanding these different types can help businesses choose the most suitable process for their specific needs.

One common type of injection molding process is called thermoplastic injection molding. This method involves melting thermoplastic material and injecting it into a mold cavity to form the desired shape. Thermoplastics are known for their versatility and can be recycled, making them a popular choice for a wide range of applications.

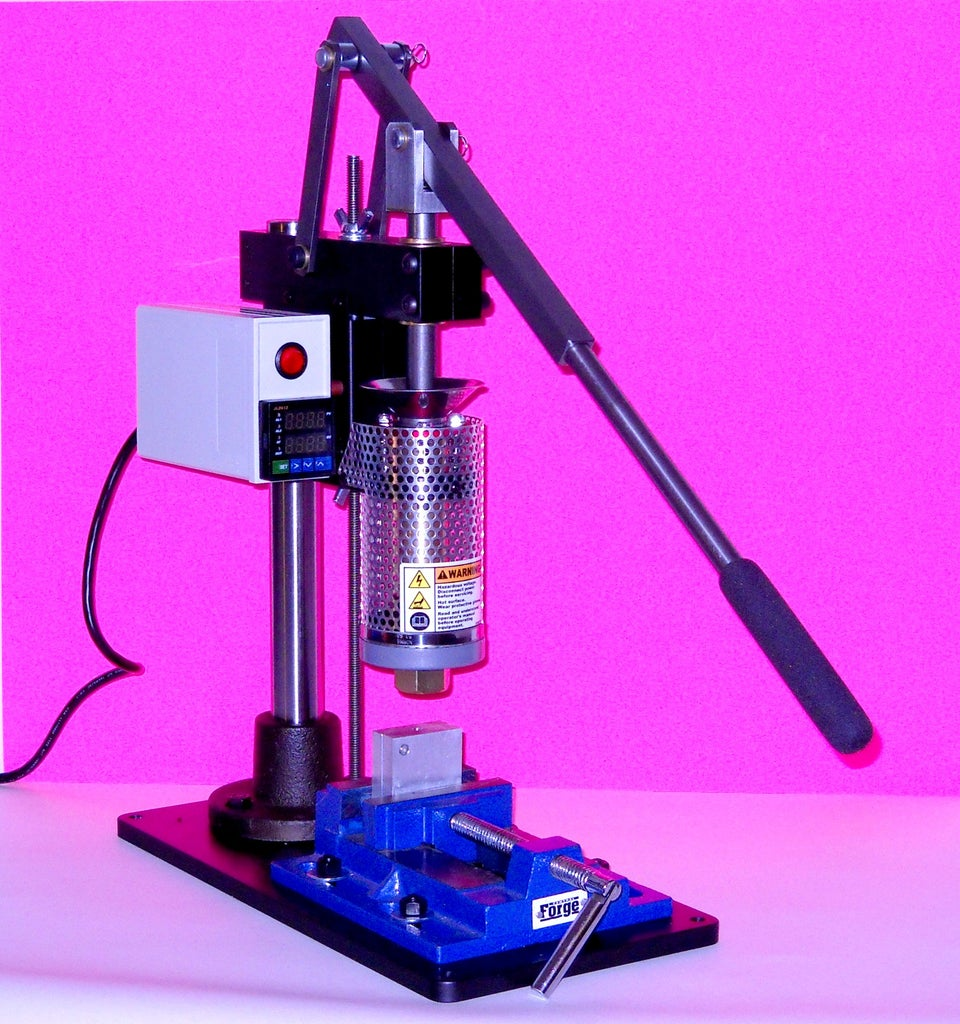

Another type of injection molding process is known as insert molding. This process involves inserting a pre-formed component, such as a metal part, into the mold before injecting the material. Insert molding allows for the creation of complex parts with multiple materials or components, enhancing the overall functionality of the final product.

Key Considerations When Choosing an Injection Molder

When selecting an injection molder, it is essential to first assess their experience and expertise. Look for a company that has a proven track record in producing high-quality molds that meet your specifications. Consider their reputation within the industry and inquire about past projects to gauge their level of proficiency.

Another crucial factor to consider is the range of materials and technologies the injection molder offers. Ensure that the company can work with the specific materials you require for your products and that they keep up-to-date with the latest advancements in injection molding technology. This will help guarantee that your molds are manufactured using the most efficient and innovative methods available.

Lastly, take into account the location and logistical aspects of working with the injection molder . Opting for a company that is geographically convenient can streamline communication and shipping processes, potentially reducing lead times and costs. Additionally, inquire about their capacity and flexibility to accommodate your production needs, ensuring a smooth and efficient collaboration.

Benefits of Outsourcing Injection Molder Services

Utilizing outsourced injection molder services can significantly streamline your production processes. By partnering with a trusted injection molder, you can access specialized expertise and cutting-edge technology that may not be viable in-house. This can result in improved product quality, faster time-to-market, and overall cost savings.

Outsourcing injection molder services allows your business to focus on its core competencies, such as product design and marketing strategies, while leaving the intricate molding processes to the experts. This division of labor can lead to enhanced efficiency within your organization, ultimately boosting productivity and competitiveness in the market.

Moreover, collaborating with external injection molders grants you the flexibility to scale your production output according to demand fluctuations. Whether you need a high volume of components or require quick turnaround times for prototypes, outsourcing these services provides the agility needed to adapt to changing business conditions swiftly and effectively.